DILO Certified Gas: Mixing, reclaiming & analysing of gases

The better alternative. For everyone involved.

Gases such as SF6 or other insulating and arc quenching gases are indispensable for the safe operation of medium and high-voltage applications thanks to their unique physical properties. Over time, however, the arc quenching and insulating gases can become contaminated, which can greatly reduce their arch quenching and insulating properties: In such cases, the gas used must be replaced with new gas. Yet every newly produced kilogram of gas means potential new emissions and an additional burden on the environment. DILO's solution is simple: Turning old into new.

Eco-efficient alternative to new gas

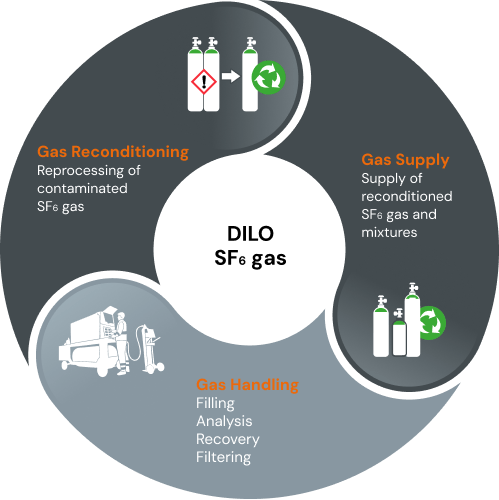

The idea behind DILO Certified Gas is remarkably simple: Instead of producing new SF6 gas or a new alternative arc quenching and insulating gas mixtures, the used gas is simply reclaimed or mixed. DILO offers users and operators of gas-insulated equipment the option to either mixing or completely reclaiming the contaminated gas. This is not only more sustainable than purchasing new gas - it has been proven to deliver equal or even superior quality.

DILO Services for alternative arc quenching and insulating gases

DILO relies on precise gravimetric processes for the production of alternative arc quenching and insulating gas mixtures. This ensures that all components are precisely dosed and homogeneously mixed. The result is certified gas mixtures based on C4-FN, which guarantee maximum mixing accuracy and lasting stability.

At DILO, you get everything from a single source: from mixing and separation to reclaiming, analysing and delivery in TÜV-certified pressure vessels - either in gaseous or partially liquefied form. Upon request, we also take care of collection, return, and refilling directly into your system.

Reclaiming alternative arc quenching and insulating gases

DILO services for alternative arc quenching and insulating gases at a glance

- Mixing of alternative arc quenching and insulating gases (C4-FN and other gas mixtures)

- Separation/reclaiming and return

- Analytical services in the DILO laboratory

- Vessel services: Acquisition of purchase/rental cylinders, TÜV - repeat inspection, scrapping

Our checklists for alternative arc quenching and insulating gas enquiries

DILO services for SF6 gas

For reclaiming used SF6 gas, DILO relies on a cryogenic separation process. By precisely applying pressure and low temperatures, by‑products are removed in several stages until pure SF6 gas with a purity of ≥ 99.9% is obtained, which can then be reused.

At DILO, you receive the complete service from a single source: from collection to reclaiming and analysis to the return delivery of the reclaimed gas Upon request, we can also take care of used gas cylinders, pressure vessels and gas that can no longer be used - including disposal, repeated inspection by TÜV and reuse.

Reclaiming of SF6 gas

DILO Certified SF6 gas compared with IEC and ASTM standards

| Substance | DILO Quality"Certified Gas" | IEC 60376:2018 (New gas) | ASTM D2472-15 |

|---|---|---|---|

| SF6 | > 99.9 Vol.-% (> 99.99 wt%) | > 98.5 Vol.-% | ≥ 99.8 wt% |

| H2O | ≤ 8 µl/l | < 200 µl/l | ≤ 8 µl/l |

| Frost point (1 atm) | ≤ -62 °C | -36 °C | -62 °C |

| Total acidity (HF equiv.) | < 0.1 µl/l | < 7 µl/l | ≤ 0.3 ppmw |

| Air | < 500 µl/l | < 10,000 µl/l | ≤ 500 ppmw (2500 µl/l) |

| CF4 | < 500 µl/l | < 4,000 µl/l | ≤ 500 ppmw (830 µl/l) |

| Oil mist | < 1 mg/kg | < 10 mg/kg | – |

| SO2 | < 0.1 µl/l | – | – |

DILO services for SF6 gas at a glance

- Supply of already reclaimed SF6 gas with a purity of ≥ 99.9%

- Reclaiming and return/disposal of contaminated SF6 gas

- Analytical services in the DILO laboratory

- Vessel services: purchase of new/rental cylinders, TÜV periodic inspection, scrapping

- Collection and return transport

Our checklists for SF6 gas enquiries

Analytical services in the DILO laboratory

The DILO laboratory offers a wide range of gas chromatographic and FT-IR spectroscopic analyses in the field of sulphur hexafluoride (SF6) its by-products and decomposition products as well as alternative C4-FN based arc quenching and insulating gas mixtures. Additional analytical questions in the field of gas analysis can also be addressed upon request Please do not hesitate to contact us.

FT-IR spectroscopic rapid analysis

With FT-IR spectroscopy, DILO analyses gas mixtures quickly and precisely - without complex sample preparation. The method utilises the characteristic light absorption of the molecules and creates a spectrum from which the composition and concentrations are determined. This allows both SF6 decomposition products and alternative arc quenching and insulating gas mixtures (e.g. based on C4-FN) can be reliably detected. Measurements achieve accuracies of down to ≤ 1 ppm and are analysed by DILO experts.

- Accuracy down to ≤ 1 ppm: even the smallest concentrations are reliably detected

- Easy sample delivery: only one gas cylinder with a minimum pressure of (0.3 bar relative) is required

GC/MS detailed analysis

With GC/MS analysis, DILO covers a very broad analytical spectrum:: gas mixtures are first separated chromatographically and then analysed by mass spectrometry. This allows common gases such as C4‑FN, SF6 or oxygen to be reliably detected in the ppm range, as well as even the smallest by‑products and decomposition products down to the ppb range. Every sample is examined by DILO specialists and documented with a certified measurement report.

- Highest precision: detection of decomposition products down to ≤ 100 ppb

- No sample preparation: simply submit the gas cylinder with a minimum relative pressure of 0.3 bar

Analysis of submitted samples

Would you like to have your gas samples analysed by DILO?

No problem. To ensure that your sample arrives safely and without contamination at our laboratory, DILO supports you in organising sampling and transport. Upon request, you will receive a fully equipped sampling kit containing all components for professional sampling, including sample vessels, hoses and connections. DILO also takes care of the logistics for sample transport to ensure a safe and efficient process.

- Safe sampling: fully equipped DILO kits for correct sampling

- Smooth process: complete organisation of transport and laboratory delivery

Your benefts at a glance

- Lower costs: no purchase costs for new SF6 gas

- Tax savings: no CO2 taxes for importing new SF6 gas, no regional taxes on the use of new SF6 gas

- Effective environmental protection: no resource consumption for the production of new SF6 gas, no environmentally harmful disposal of used SF6 gas

- Certified quality and waste management: all processes comply with IEC 60376, ASTM D2472-15 and GB/T 12022/2014 and are fully documented

- Maximum transparency: complete traceability from sampling to refilling - ensuring full safety and traceability

News

CONTACT

Interested in DILO Certified Gas Services?

Whether mixing, reclaiming or analysing: we will be happy to advise you and find the best solution for your project. Please do not hesitate to contact us.